Detecting anomalies in production is never easy. Although humans are very accurate and extremely good at image processing, not only do we get tired and often make mistakes, there are some things we just can’t see.

Our recent project for a major automotive manufacturer is a perfect example. In the automotive industry, you must look very carefully for incorrectly painted surfaces so that no customer gets a defective part. Mistakes are simply unacceptable.

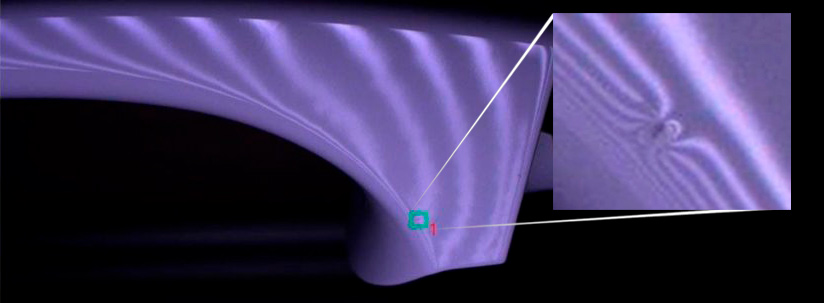

By using special lighting techniques and camera modules combined with our in-house trained convolutional neural networks, we were able to create a system able to detect and classify defects that are less than 0.1 mm in size, with an accuracy of more than 95%. Meaning that even if a defective part comes through, there is almost no chance of finding it with the human eye. Not without perfect lighting and knowing where and what to look for.

Our lighting techniques on incorrectly painted car door handles

![Podcast: What is AI on the Nejen o IT světě show [Czech Only]](https://www.peoly.com/wp-content/uploads/2022/02/Screenshot-2021-04-19-173000.jpg)